-

Ceramiczne łożyska kulkowe

-

608 łożysk ceramicznych

-

Hybrydowe łożyska ceramiczne

-

Ceramiczne łożyska wałeczkowe

-

Ceramiczne łożysko oporowe

-

Ceramiczne łożysko ślizgowe

-

Zaawansowana ceramika strukturalna

-

Kulka z azotku krzemu

-

Kulka z węglika krzemu

-

Kulka ceramiczna z cyrkonu

-

Łożyska kulkowe z węglika krzemu

-

Łożysko kulkowe z azotku krzemu

-

Ceramiczne łożysko cyrkonowe

-

Uszczelnienie mechaniczne

-

Łoże z węglowodorów krzemowych

-

RobertaIch łożyska ceramiczne są bardzo precyzyjne, dobrej jakości i niedrogie. Współpracujemy od wielu lat.

RobertaIch łożyska ceramiczne są bardzo precyzyjne, dobrej jakości i niedrogie. Współpracujemy od wielu lat. -

Olga WeinbergFirma ta jest naszym niezawodnym i profesjonalnym dostawcą łożysk ceramicznych od wielu lat, ich łożyska ceramiczne, które są stosowane w naszej pompie są dobrej jakości.

Olga WeinbergFirma ta jest naszym niezawodnym i profesjonalnym dostawcą łożysk ceramicznych od wielu lat, ich łożyska ceramiczne, które są stosowane w naszej pompie są dobrej jakości.

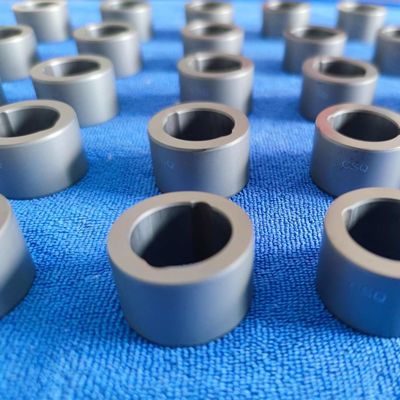

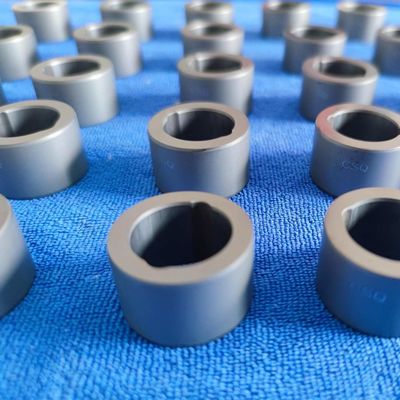

Advanced Ceramic Sleeve For Industrial Applications High Temperature Tolerance And Corrosion Resistance

| Miejsce pochodzenia | Chiny |

|---|---|

| Nazwa handlowa | CSQ |

| Orzecznictwo | FDA,REACH,ROHS,ISO9001,ISO14001,ISO45001 |

| Numer modelu | niestandardowe produkty |

| Minimalne zamówienie | 20-50 szt |

| Cena | negotiable |

| Szczegóły pakowania | Pianka + karton |

| Czas dostawy | 20-45 dni roboczych |

| Zasady płatności | T/T |

| Możliwość Supply | 2000 SZTUK miesięcznie |

Skontaktuj się ze mną, aby otrzymać bezpłatne próbki i kupony.

WhatsApp:0086 18588475571

czat: 0086 18588475571

Skype'a: sales10@aixton.com

W razie jakichkolwiek wątpliwości zapewniamy całodobową pomoc online.

x| nazwisko | Dostosowane ceramiczne łożysko ślizgowe | Kategoria | Ceramiczne łożysko ślizgowe |

|---|---|---|---|

| Materiał | Węglik krzemu | Wielkość | Dostosowane, zgodnie z rysunkami |

| Zastosowanie | Lakierki | Pakiet | Pianka + karton |

| Jakość | Wysoka precyzja, długa żywotność, serwis OEM | Specyfikacja | Rozmiar standardowy i dostosowany |

| Attribute | Value |

|---|---|

| Name | Customized ceramic sliding sleeve bearing |

| Category | Ceramic sliding bearing |

| Material | Silicon carbide |

| Size | Customized, according to drawings |

| Application | Pumps |

| Package | Foam + carton box |

| Quality | High precision, Long life, OEM service |

| Specification | Standard size and customized |

Custom-engineered silicon carbide (SiC) sliding bearing sleeves represent a cutting-edge solution for demanding industrial, automotive, and aerospace applications. These precision components deliver superior performance compared to conventional steel bearings.

- Exceptional Corrosion Resistance: Silicon carbide's inherent stability ensures outstanding resistance to corrosive chemicals and harsh environments.

- Reduced Friction & Wear: The ultra-smooth, high-hardness surface minimizes friction and wear, enhancing operational efficiency.

- High-Temperature Durability: Maintains structural integrity in extreme heat, perfect for high-temperature applications.

- Max Temperature up to 1650℃

- Low density: 3.15-3.18 g/cm³

- High strength and hardness (2800 HV5)

- Low thermal expansion: 4.0 (10-6/℃)

- High thermal conductivity: 120 W/m°K

- High elastic modulus: 410GPa

- Superior chemical stability, resistance to acid and alkali corrosion

- Higher temperature resistance (up to 1650℃)

- Superior performance in thermal cycling

- Enhanced anti-seizure & anti-jamming properties

- Oil-free operation capability

- Exceptional corrosion resistance

- Electrical insulation & anti-static properties

- Non-magnetic & contamination-resistant

With three factories in China and advanced pressing, sintering, and processing machines, we specialize in customized ceramic bearing solutions. Our company possesses eleven invention patents and has been manufacturing ceramic bearings since 1982.

- Free sample bearings available

- ISO standard compliant production

- In stock bearings for quick delivery

- Small order quantities accepted

- OEM bearing service

- Customized bearing solutions

- Competitive factory pricing

We are a factory in Beijing, China with over 40 years of experience producing ceramic bearings, serving domestic and international clients.

We produce samples before mass production, conduct precise inspections, and use double packaging (foam + carton) to ensure product quality.

As an integrated company with three factories and modern equipment, we offer better delivery times, product quality, and customized solutions.

We cooperate with raw material suppliers to ensure stable quality and pricing. Our customer-focused approach delivers quality products and after-sales service. Contact us to discuss your requirements.